|

|

|

|

|

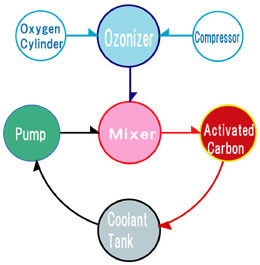

Deodorization and sterilization

of fouled cutting oil by ozonization

| System flow of ozonization |

|

|

The unit prevents cuting oil from fouling at a low cost by circulating it in the specified mixing tank

with a built-in ozone generator where anaerobic bacteria are sterilized. |

| |

You can set it up easily by connecting the cutting oil tank with the

ozonization unit. |

| Installation is recommended with a new oil, however, the unit works well

even with a fouled oil and removes its rotten smell. |

| No waste is generated out of the unit because of its chemical decomposition

mechanism. |

|

| |

|

|

Oxygen |

|

Ozon |

|

Clean Cutting Oil |

|

Cutting Oil |

|

|

| |

|

| Example of bacteria sterilization |

|

|

|

|

|

Total number of bacteria in cutting oil can be checked by a bacteria checker. |

|

|

|

|

|

|

|

(Photographs show the oil samples using oxygen.) |

|

before ozonization |

|

after ozonization |

|

|

|

|

|

|

| Example of deodorization |

|

|

|

|

|

Hydrogen sulfide and mercaptan, sources of the foul odor, are decreased by ozonization and those chemicals can be checked by a detector tube. |

|

|

| (Photographs show the detector tubes for mercaptan.) |

|

|

|

|

before ozonization |

|

after ozonization |

|

|